MIZHI

TECHNOLOGY

Hotline

+86-136-8495-9862

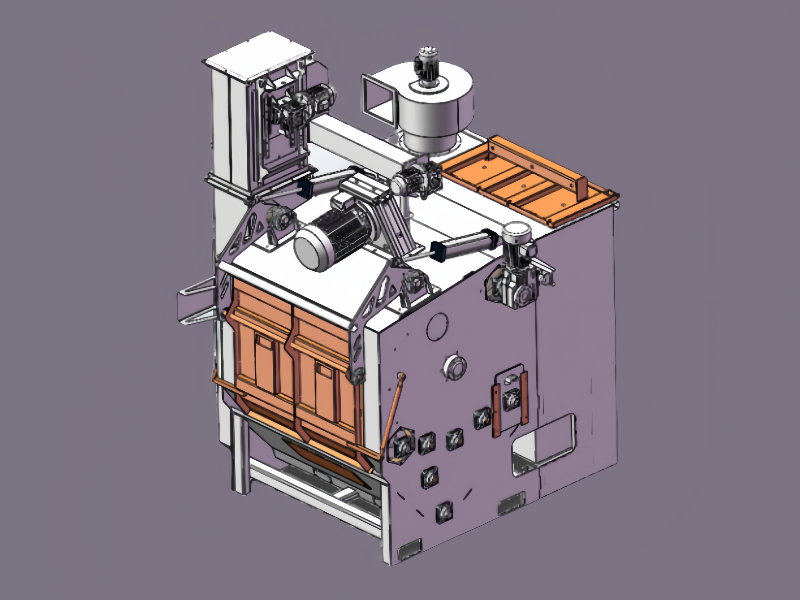

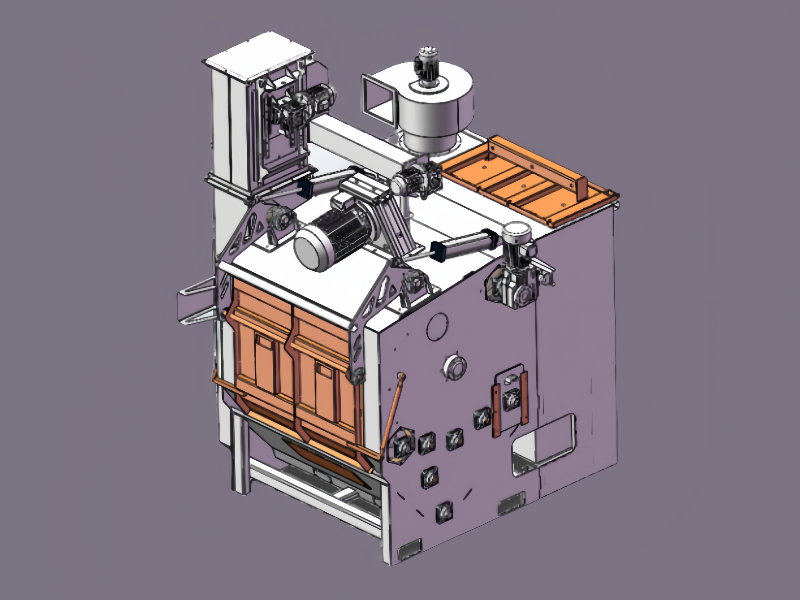

Introduction

A Tumble Shot Blasting Machine for Small & Medium Castings and Forgings is a specialized industrial device designed to clean, descale, and prepare the surfaces of small to medium-sized castings and forgings. This machine uses a tumbling mechanism to gently agitate the workpieces, ensuring uniform exposure to the shot blasting process. It is particularly effective for batch processing of these components, ensuring high production levels and consistent surface treatment.

Applications

1. Foundry: Ideal for de-sanding, stripping, and preparing castings for further processing.

2. Forge: Effective for deburring, removing laminate and coating, and achieving a homogeneous surface finish.

3. Aluminum Die-Casting: Provides uniform surface blasting finishing.

4.General Manufacturing: Suitable for cleaning and surface treatment of small to medium-sized metal parts.