1. Adopt ABB brand blast motor,with excellent controllable manufacturing process; good sealing and dynamic balance and stable and reliable performance.

2. The shell is using 8mm high quality carbon steel plate through laser cutting and precision bending welding. Equipped with a special jig for welding to ensure the parallelism of the two shell ends and the concentricity of the hole.

3. The die steel CNC top guard is processed by precision machining, and the machining accuracy reach to ± 0.01.Low pressure vacuum heat treatment after CNC precision machineing.

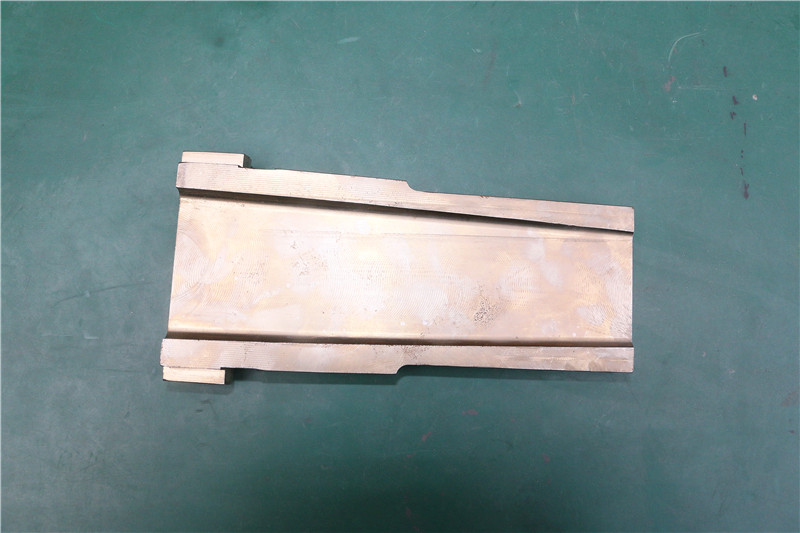

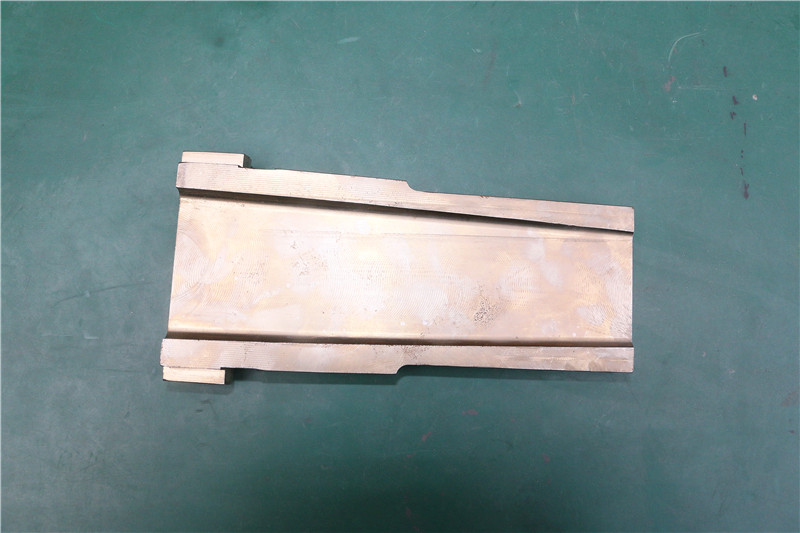

4. End guard is made of high wear resistant manganese 13 steel plate, through laser cutting.

5. The die steel CNC side guard is processed by precision machining, and the machining accuracy reach to ± 0.01.Low pressure vacuum heat treatment after CNC precision machineing.

6. The die steel CNC control cage is processed by precision machining, and the machining accuracy reach to ± 0.01 with Uniform wear, good dynamic balance.Low pressure vacuum heat treatment after CNC precision machineing.

7. The die steel CNC impeller is processed by precision machining, and the machining accuracy reach to ± 0.01 with Uniform wear, good dynamic balance.Low pressure vacuum heat treatment after CNC precision machineing.

8. The die steel CNC blade is processed by precision machining, and the machining accuracy reach to ± 0.01 with Uniform wear, good dynamic balance.Low pressure vacuum heat treatment after CNC precision machineing.

9. The die steel CNC vane wheel is processed by precision machining, and the machining accuracy reach to ± 0.01, The surface hardness can reach HRC58-62.

10. Uselife of the above wearing parts are more than three times that of casting products (shot material: S460 or less (1.5mm cast steel shot), hardness: HRC40-50).