MIZHI

TECHNOLOGY

Hotline

+86-136-8495-9862

Uses

Mini sand blasters are compact and portable devices designed for a variety of surface treatment applications. They use compressed air to propel abrasive materials at high speed onto a surface to achieve the desired effect. Here are some of the primary uses:

1.Surface Cleaning:

Mini sand blasters are used to remove rust, paint, and other contaminants from metal surfaces. For example, they can be used to clean car bodies before painting to ensure a smooth and durable finish.

They are also effective in removing residual stress and improving the surface hardness of materials, which enhances the durability of the treated surfaces.

2.Surface Preparation:

These machines prepare surfaces for painting or coating by creating a rough texture that increases the adhesion of new coatings. This is crucial in industries like automotive and aerospace, where high-quality surface preparation is necessary for the longevity and performance of coatings.

They are also used for etching and engraving on surfaces like glass, crystal, jade, marble, and ceramics.

3.Rust Removal:

Mini sand blasters are highly effective in removing rust from metal surfaces, achieving high cleaning standards (up to Sa3 grade). This is particularly important in the maintenance of tools and machinery.

4.Paint Stripping:

They are used to remove multiple layers of paint from various materials, making them ideal for automotive repair shops and industrial maintenance.

5.Delicate Jobs and Hobbyist Use:

Mini sand blasters are ideal for smaller blasting jobs and hobbyist-level blasting. They are also suitable for restoration works that require low pressure and precision, such as tombstones.

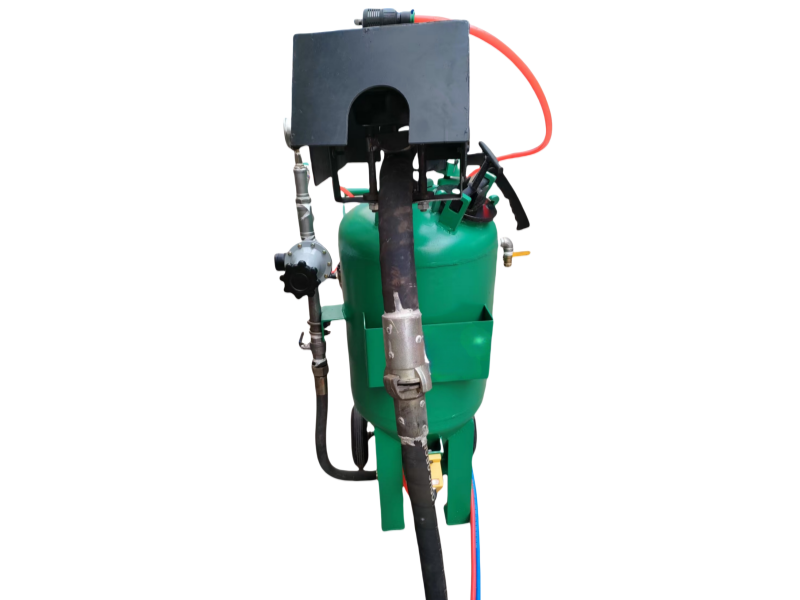

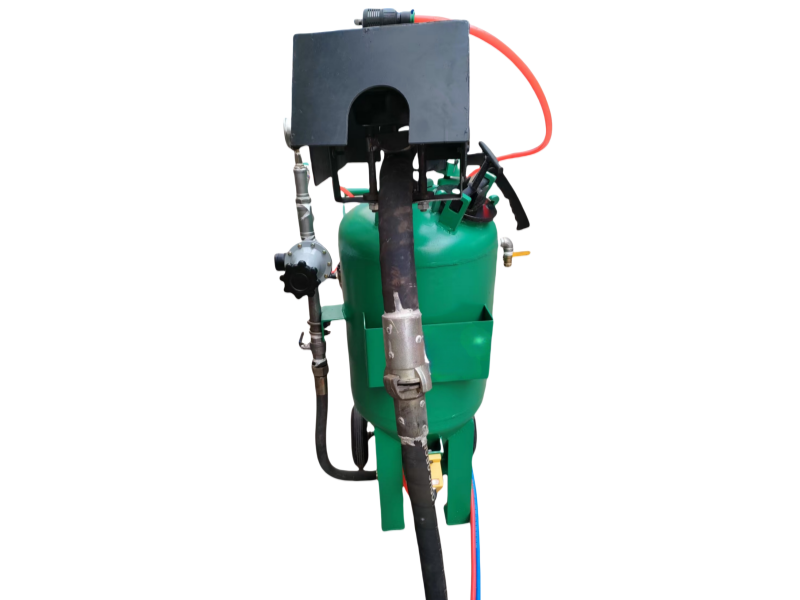

A dustless water sand blasting pot, also known as a wet blast pot, works on the principle of combining water with abrasive media and using compressed air to propel the mixture onto a surface at high speed to achieve cleaning, stripping or other surface preparation tasks. Here's a detailed explanation of its working principle:

Blasting Process

1.When the air compressor starts working, it pressurizes the blast pot and generates a stream of high-pressure air. This high-pressure air flows into the blast pot and mixes with the abrasive media and water.

2.The abrasive media and water form a slurry-like mixture. The high-pressure air acts as the propelling force, carrying the mixture through the blast hose and out of the nozzle at high speed.

3.As the mixture strikes the surface to be treated, the water in the system plays a crucial role. It helps to cushion the impact of the abrasive media on the surface, reducing friction and heat generation. This prevents damage to delicate materials like metal or fiberglass and avoids warping caused by excessive heat.

4.The water also effectively captures and suppresses dust particles produced during the blasting process. When the abrasive media impacts the surface and breaks apart or grinds the contaminants, the dust particles are surrounded and bound by the water, preventing them from becoming airborne. This significantly reduces dust pollution in the surrounding environment and minimizes the risk of dust-related health problems for operators and nearby personnel.