MIZHI

TECHNOLOGY

Hotline

+86-136-8495-9862

Definition

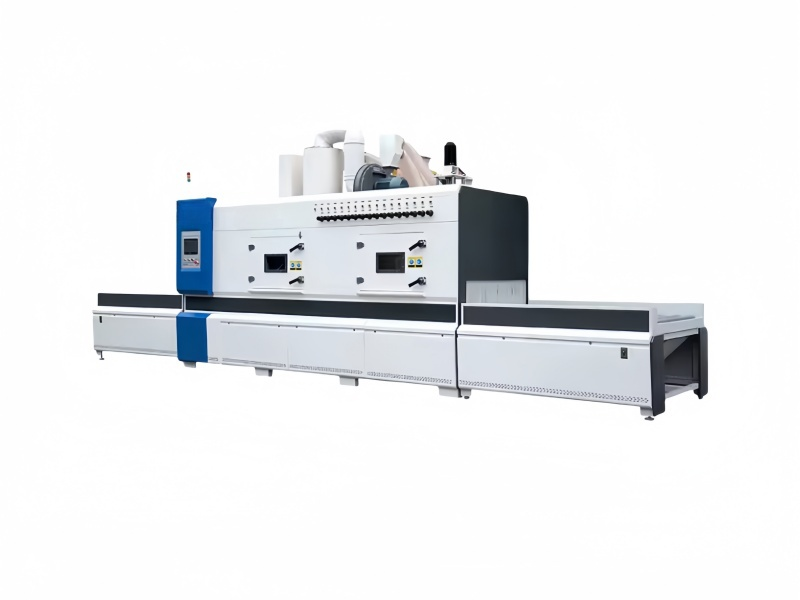

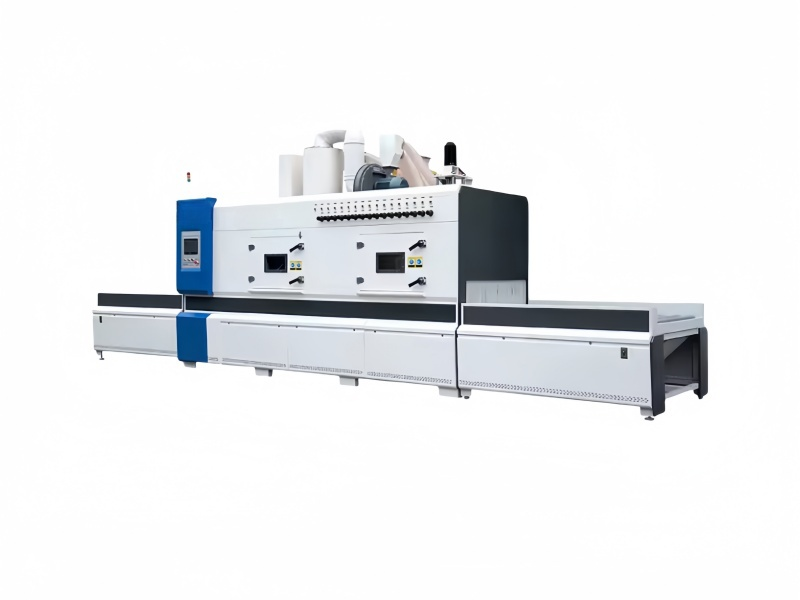

A Roller Conveyor Sand Blasting Machine is an industrial device designed for the surface treatment of flat or long workpieces, such as steel plates, profiles, pipes, or beams. It uses a roller conveyor system to transport the workpieces through a blasting chamber where abrasive media are propelled at high velocity to clean, descale, derust, and prepare surfaces.

Uses

1.Surface Cleaning and Descaling: Removes rust, scale, and contaminants from steel plates, profiles, and pipes.

2.Paint and Coating Removal: Prepares surfaces for repainting or other treatments.

3.Surface Preparation: Improves surface finish and increases paint adhesion.

4.Deburring and Finishing: Smooths rough edges and improves surface quality.

The working principle of sand blasting machines involves the use of compressed air or a mechanical means to propel abrasive materials onto a surface. There are two main types of sand blasting machines based on their working principle:

1.Air-Powered Sand Blasters:

These machines use compressed air to accelerate abrasive particles through a nozzle, which is directed at the surface to be treated . The force of the abrasive particles removes surface materials or contaminants.

The pressure can be adjusted depending on the material being blasted and the desired effect.

2.Mechanical Sand Blasters (Wheel Abrators):

These machines use a spinning wheel to propel abrasive materials onto the surface . The wheel's centrifugal force accelerates the abrasive particles, which are then directed at the workpiece.

This type is more suitable for heavy-duty applications and can handle larger volumes of abrasive material.