MIZHI

TECHNOLOGY

Hotline

+86-136-8495-9862

Introduction

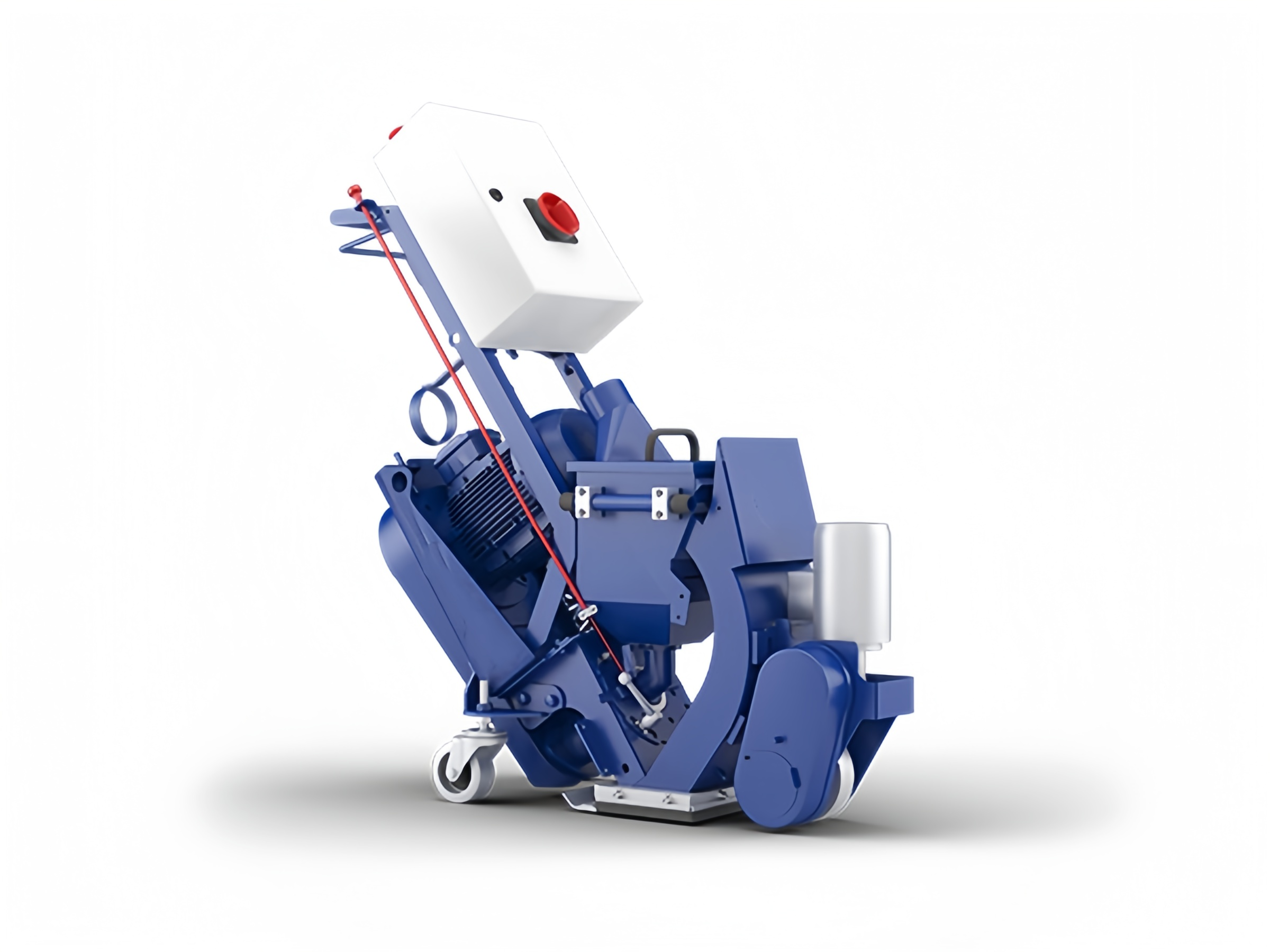

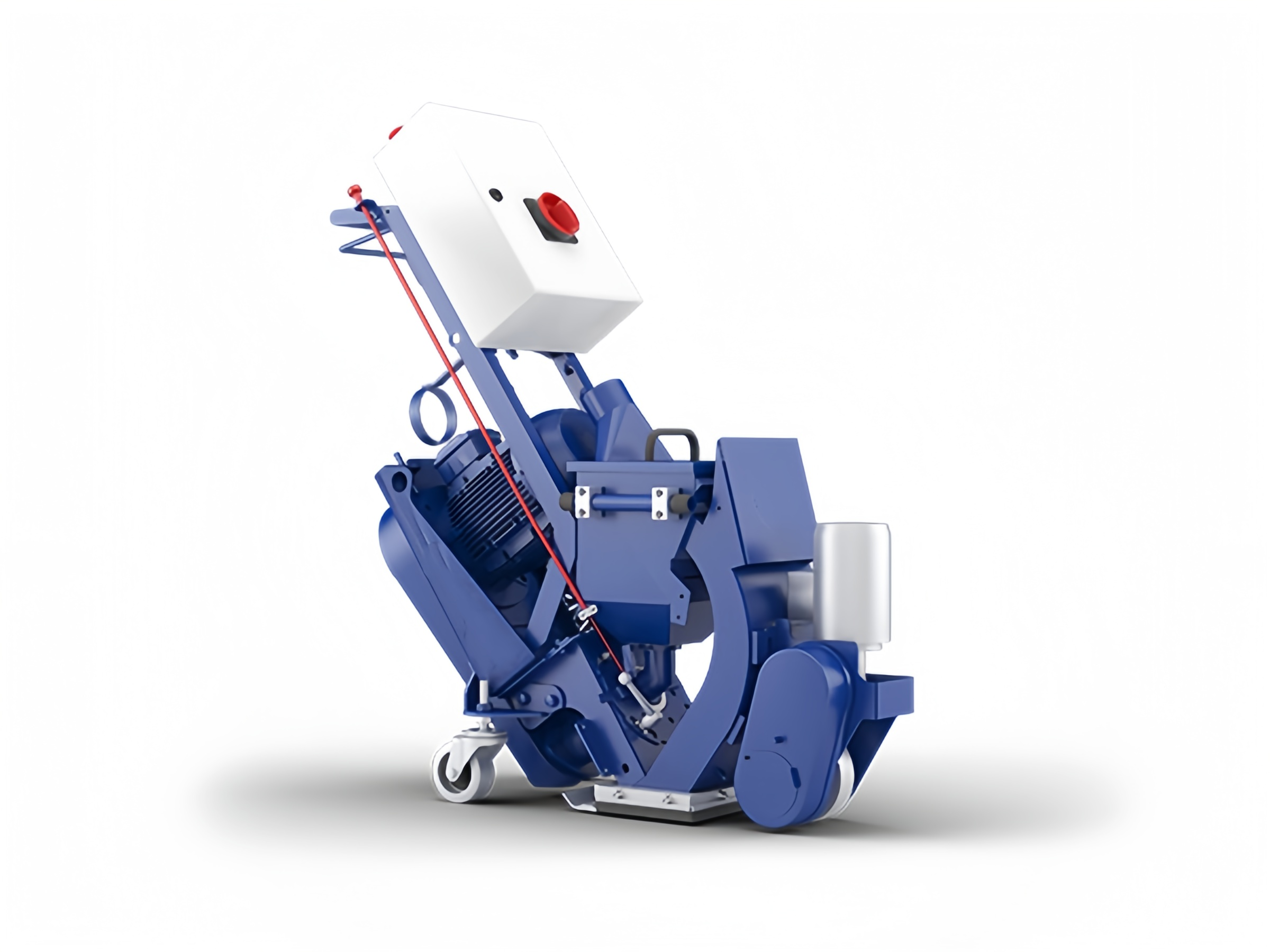

A portable steel plate shot blasting machine is a type of surface treatment equipment that uses shot blasting technology to clean, remove rust, scale, and other contaminants from steel plates. It is designed to be mobile and easy to transport, making it suitable for various industrial applications.

Applications

This machine is widely used in various industries, including:

1.Construction: For cleaning and preparing steel plates used in building structures.

2.Shipbuilding: To clean ship decks and remove rust from steel components.

3.Bridge Construction: For surface treatment of steel bridge decks to ensure proper adhesion of anti-corrosion coatings.

4.Manufacturing: To prepare steel plates for welding, painting, or other manufacturing processes.

The Portable Steel Plate Shot Blaster works as follows:

1.Positioning

Place the steel plate on the machine's worktable and secure it to ensure stability during blasting.

2.Blasting

The shot blaster's wheel, with a high-speed impeller and blades, accelerates and throws shot (steel shot or grit) onto the plate. The shot impacts the surface at high speed, removing rust, scale, and dirt while creating a roughened surface for further processing.

3.Recovery and Separation

The shot falls and is collected by a recovery system, which transports it to a separator. Here, usable shot is separated from dust and broken particles, then returned to the wheel for reuse.

4.Dust Collection

A dust collection system captures and filters the dust generated during blasting, releasing clean air to maintain a clean environment.

5.Control

Operators can set parameters like blasting time and intensity via a control panel, enabling precise control of the process.